Specification

- स्पिंडल स्पीड

- Recommended: 8,000-16,000 RPM (Varies by diameter and job)

- कटिंग स्पीड

- Recommended: 80-200 m/min (varies with material and tool diameter)

- शोर का स्तर

- Low (Depends on operating conditions)

- एप्लीकेशन

- Milling, Contouring, Slotting, 3D Surface Machining in Mold, Die Steel, Alloy Steel, Cast Iron

- टूल टाइप

- End Mill/Carbide Ball Nose Cutter

- प्रॉडक्ट टाइप

- 2 Flute Ballnose End Mill

- मटेरियल

- Copper (Base Material)

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- वजन (किग्रा)

- Varies by size (Typically Lightweight)

- आयाम (एल* डब्ल्यू* एच)

- Varies by model; e.g., diameter x length as per specifications

- क्षमता

- Suitable for materials up to 55HRC

- फ़ीचर

- रंग

About

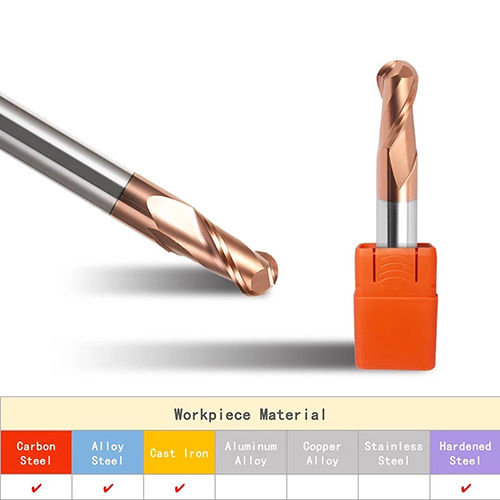

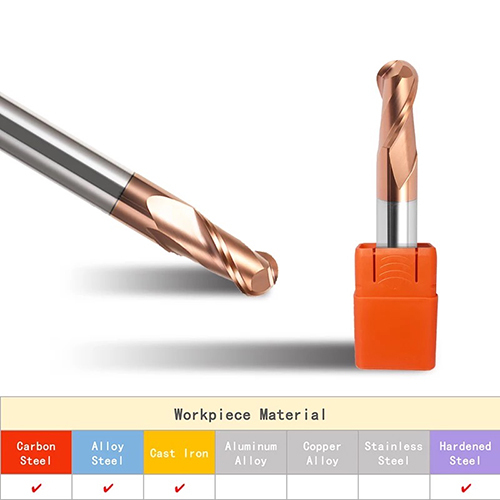

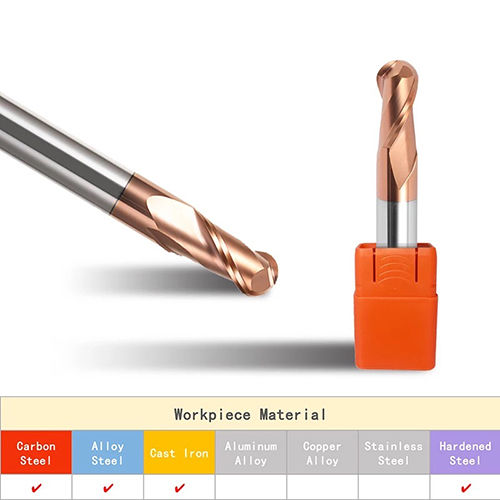

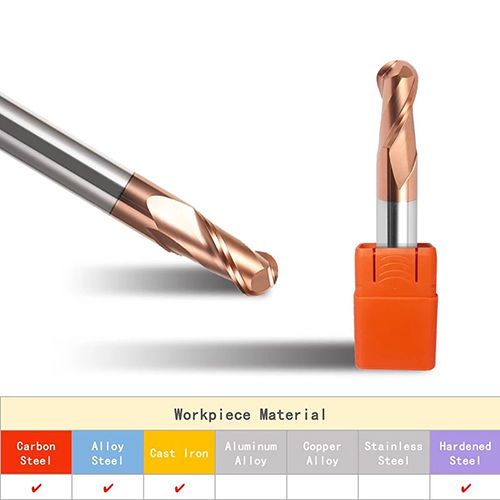

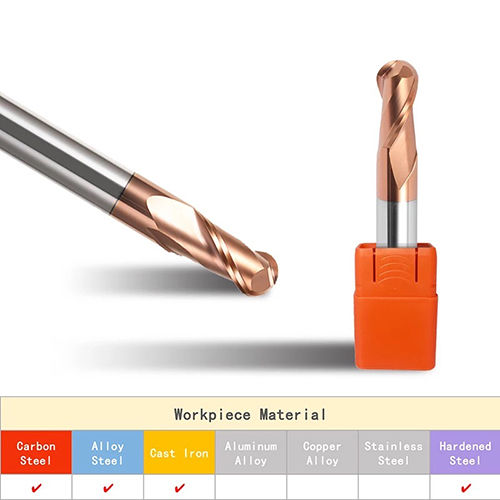

Ending Soon: Seize the praiseworthy 10300 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED end mill at a remarkable price cut! This valiant tool features a heroic TiCN coating, ensuring superior wear resistance, high hardness (55 HRC), and precise cutting. Select from various sizes to match your machining requirements. Whether youre tackling copper, brass, aluminum, or alloy steel, expect heroic performance and consistently fine surface finishes (Ra 0.2 m). Its robust design excels in milling, contouring, slotting, and 3D surface machining. Crafted with pride by an ISO 9001:2015 certified manufacturer, act swiftly: limited stock, and this offer is ending soon!

Optimal Applications and Usage Versatility

10300 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED is ideal for plant environments involved in mold, die, or component manufacturing. Its ball nose design is best-suited for 3D surface machining, finishing, slotting, and contouring of copper, brass, mild steel, and plastic materials. To achieve the most precise results and longest tool life, apply with air or oil mist cooling as per the applications demands. Use this tool manually for valiant and consistent performance in industrial settings.

Prompt Delivery and Packaging Details

Products are delivered nationwide across India using secure transportation channels after confirmation of order at the list price. Expect a standard delivery time of 27 working days depending on your location. Sample pieces are available upon request for qualified buyers. Packaging is done in sturdy, protective cases to prevent any damage during transportation, reflecting our praiseworthy commitment to quality and customer satisfaction. Reach out for any customization or urgent requirements to ensure timely, reliable service.

Optimal Applications and Usage Versatility

10300 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED is ideal for plant environments involved in mold, die, or component manufacturing. Its ball nose design is best-suited for 3D surface machining, finishing, slotting, and contouring of copper, brass, mild steel, and plastic materials. To achieve the most precise results and longest tool life, apply with air or oil mist cooling as per the applications demands. Use this tool manually for valiant and consistent performance in industrial settings.

Prompt Delivery and Packaging Details

Products are delivered nationwide across India using secure transportation channels after confirmation of order at the list price. Expect a standard delivery time of 27 working days depending on your location. Sample pieces are available upon request for qualified buyers. Packaging is done in sturdy, protective cases to prevent any damage during transportation, reflecting our praiseworthy commitment to quality and customer satisfaction. Reach out for any customization or urgent requirements to ensure timely, reliable service.

FAQs of 10300 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED:

Q: How is the 10300 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED end mill typically used?

A: This end mill is mainly used for precision milling, contouring, slotting, and 3D surface machining in materials like copper, brass, aluminum, alloy steel, and plastics.Q: What are the main benefits of the TiCN coating on this end mill?

A: The TiCN (Titanium Carbonitride) coating provides enhanced wear resistance, greater hardness, and increased tool longevity, making it a heroic choice for demanding machining operations.Q: When should air or oil mist cooling be applied during usage?

A: Air or oil mist cooling should be used whenever possible to optimize tool life and maintain the excellent surface finish, especially when machining harder or heat-sensitive materials.Q: Where is this cutting tool typically manufactured and supplied?

A: This product is manufactured in ISO 9001:2015 certified facilities in India and supplied through authorized distributors, manufacturers, and traders nationwide.Q: What process ensures the high precision ball nose geometry?

A: High-precision grinding machines and strict quality control measures are employed during manufacturing to achieve the praiseworthy ball nose geometry required for fine finishing applications.Q: How can one request a sample before committing to a full purchase?

A: Qualified buyers can contact the supplier or distributor to request sample pieces, ensuring suitability for their specific plant application before placing a bulk order.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें