Specification

- एप्लीकेशन

- Metalworking, CNC Milling, Die & Mold, Graphite, Copper, Aluminum machining

- टूल टाइप

- Ball Nose End Mill Cutter

- शोर का स्तर

- Low (depends on machining setup)

- स्पिंडल स्पीड

- Recommended: up to 20,000 RPM

- कटिंग स्पीड

- High (varies with material and cutting parameters)

- प्रॉडक्ट टाइप

- 2 Flute Ballnose End Mill

- मटेरियल

- Copper Alloy

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- ड्राइव टाइप

- वजन (किग्रा)

- Approx. 0.05 kg

- आयाम (एल* डब्ल्यू* एच)

- Varies by size (standard ballnose mill format)

- क्षमता

- Suitable for high-precision machining

- फ़ीचर

- रंग

About

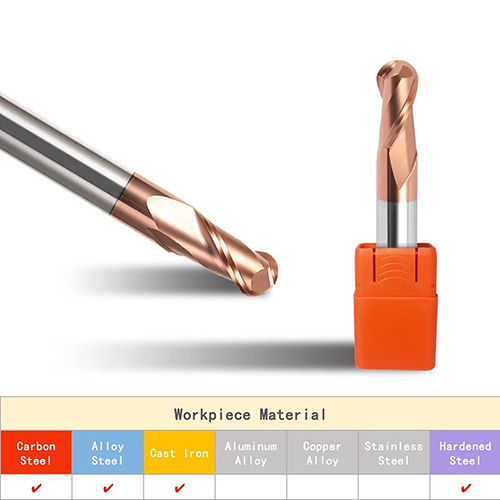

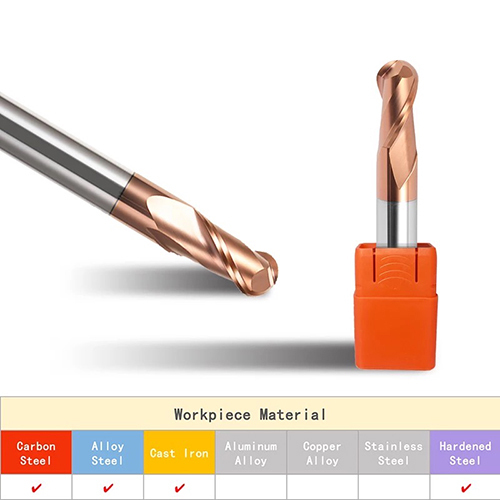

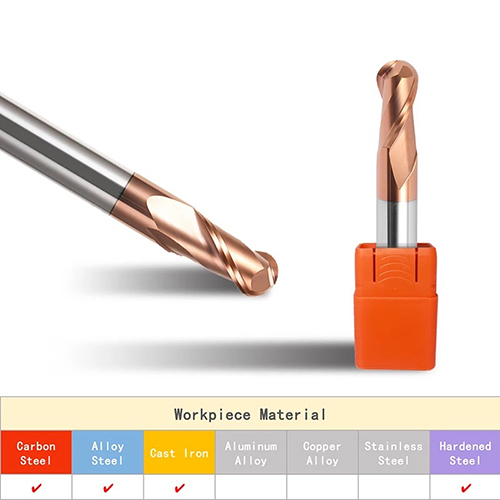

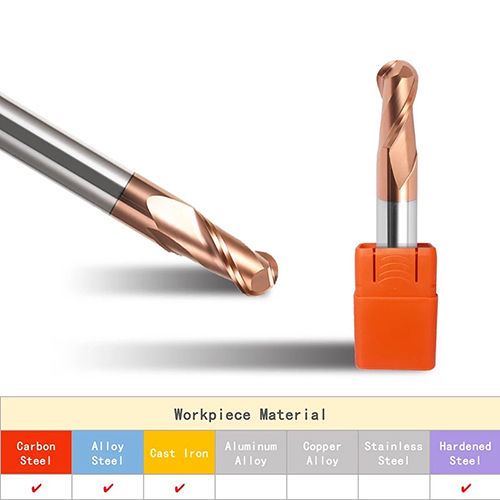

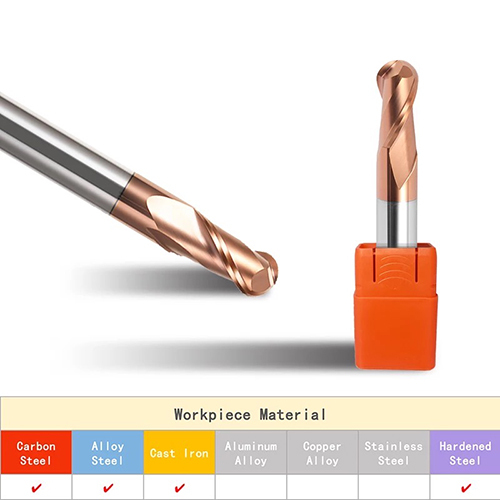

Grab the 1275 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED cutter for your machining demands! Engineered with Eminent Titanium Carbonitride (TiCN) coating, two precision flutes, and an Unbeatable 55 HRC hardness, this ball nose end mill delivers optimum performance in fine finishing, contour milling, and 3D machining. Last Chance to experience high-gloss surface finishes in copper, steel, mold steel, graphite, and aluminum applications. Featuring radial precision (0.01mm) and superior wear resistance, its an ideal choice for professionals seeking reliable, manual operation and OEM flexibility.

Application Method and Distinctive Features

The 1275 2FLUTE BALLNOSE is applied for intricate CNC milling and manual finishing across copper, steel, and graphite surfaces. Its high-gloss precision finish makes it perfect for die & mold creation, 3D machining, and contour cuts. With manual drive and a straight shank, this cutter exhibits low noise, high cutting speeds, and radial precision, ensuring consistent, optimum output. The TiCN coating offers enhanced wear resistance, further extending the tools efficiency and lifespan during demanding use.

Certifications, Packaging, and Sample Availability

Our 1275 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED cutter is backed by reputable manufacturing standards, ensuring eminent market value and reliability for export markets. Each cutter features secure packaging that safeguards integrity during shipping, whether for local distribution or overseas clients. Sample availability allows traders and manufacturers to evaluate its high-performance capability before purchase. Reliable quality assurance ensures consistent results, supporting distributors and suppliers to meet diverse customer requirements.

Application Method and Distinctive Features

The 1275 2FLUTE BALLNOSE is applied for intricate CNC milling and manual finishing across copper, steel, and graphite surfaces. Its high-gloss precision finish makes it perfect for die & mold creation, 3D machining, and contour cuts. With manual drive and a straight shank, this cutter exhibits low noise, high cutting speeds, and radial precision, ensuring consistent, optimum output. The TiCN coating offers enhanced wear resistance, further extending the tools efficiency and lifespan during demanding use.

Certifications, Packaging, and Sample Availability

Our 1275 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED cutter is backed by reputable manufacturing standards, ensuring eminent market value and reliability for export markets. Each cutter features secure packaging that safeguards integrity during shipping, whether for local distribution or overseas clients. Sample availability allows traders and manufacturers to evaluate its high-performance capability before purchase. Reliable quality assurance ensures consistent results, supporting distributors and suppliers to meet diverse customer requirements.

FAQs of 1275 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED:

Q: How is the 1275 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED used in CNC milling applications?

A: This ball nose end mill is employed for fine finishing, contour milling, and 3D machining in CNC setups, delivering precision surface finishes on copper, steel, graphite, and aluminum components.Q: What are the key benefits of Titanium Carbonitride (TiCN) coating on this cutter?

A: TiCN coating provides improved wear resistance, reduced friction, and enhanced tool life, resulting in high-gloss finishes and consistent performance even in demanding machining processes.Q: Where can this product be applied effectively?

A: It is ideal for die & mold creation, general metalworking, graphite machining, and precision milling of copper alloys, steel, and aluminum in manufacturing, automotive, and mold-making industries.Q: What is the recommended spindle speed when using this ball nose cutter?

A: For optimum results, a recommended spindle speed of up to 20,000 RPM is suggested. However, cutting speeds can vary depending on the material and specific machining settings.Q: How can samples of the 1275 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED be obtained?

A: Interested manufacturers, traders, or distributors can request product samples for evaluation prior to bulk purchase, subject to availability through our official supply channels.Q: What makes this ball nose cutter suitable for high-precision machining?

A: Its radial precision (0.01mm), two-flute design, TiCN coating, and 55 HRC hardness enable accurate, smooth, and controlled machining essential for intricate parts and detailed finishes.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें