Specification

- कटिंग स्पीड

- 120-250 m/min

- स्पिंडल स्पीड

- 12,000-20,000 RPM recommended

- टूल टाइप

- Ballnose End Mill

- पावर सोर्स

- Manual/Machine Inserted

- शोर का स्तर

- Low

- एप्लीकेशन

- Milling, 3D contouring, die and mould machining

- प्रॉडक्ट टाइप

- 4 Flute Ballnose End Mill

- मटेरियल

- Copper

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- वजन (किग्रा)

- 0.02 kg (approx)

- आयाम (एल* डब्ल्यू* एच)

- Standard: 50mm-100mm (length), Diameter 4mm-12mm

- क्षमता

- Suitable for high-speed cutting, finishing and semi-finishing

- फ़ीचर

- रंग

About

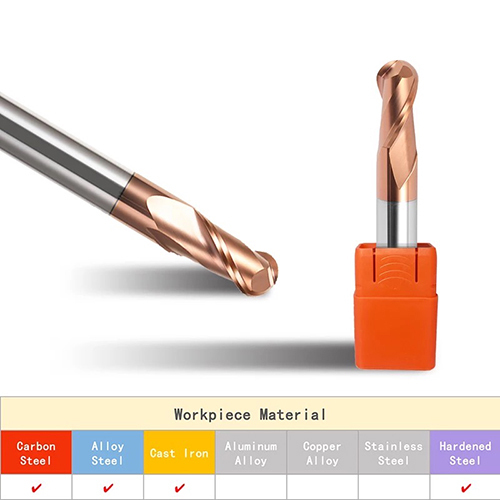

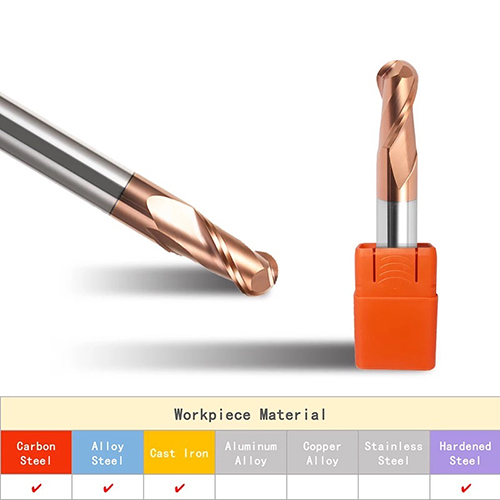

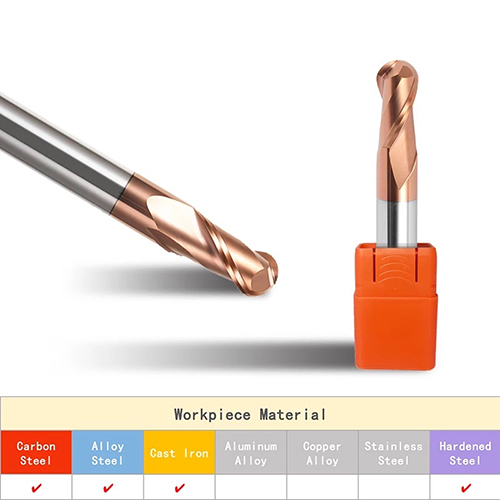

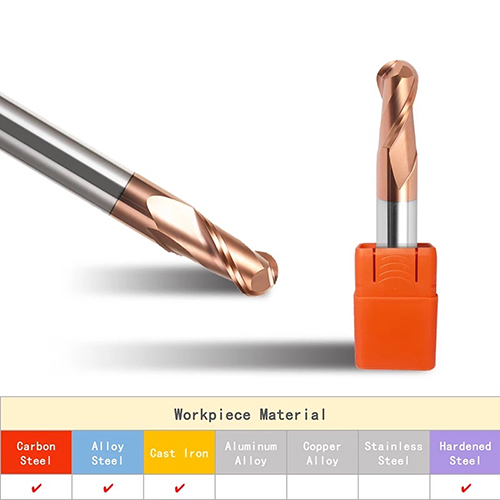

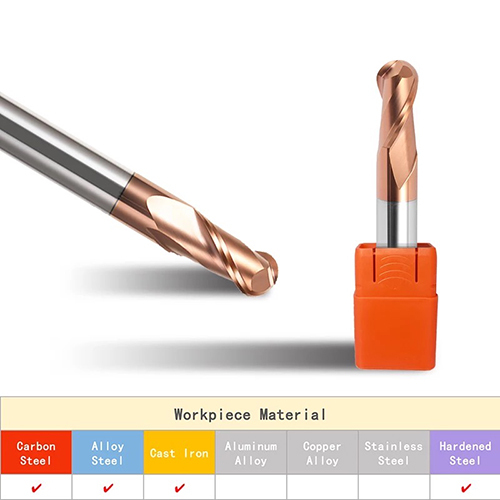

Select the top-tier 16250 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED tool for unmatched milling performance. Explore this exquisite ballnose end mill with four flutes, designed for high-speed cutting, finishing, and semi-finishing work. Pick yours for sought-after precision, featuring a robust 55HRC hardness, advanced TiCN coating, and excellent chip evacuation. This professional-grade tool boasts a 4 mm shank and cutting diameter, 50 mm overall length, 35 helix angle, and mirror-like surface finish. Suited for copper, brass, aluminum, soft steel, and die/mould machining, it ensures reliability in demanding industrial applications.

Versatility Across Applications

The 16250 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED finds use in a broad range of industries, from die and mould machining to 3D contouring and intricate milling jobs. This tool is ideal for both manual and machine-inserted operations, performing exceptionally on-site in workshops, production floors, or tool rooms. Its mirror-like surface finish and precise tolerance make it suitable for finishing and semi-finishing of copper, aluminum, brass, and soft steels, ensuring consistent quality in every application.

Distribution & Market Reach: Domestic and Global

Primarily dispatched across Indias main domestic market, this end mill is readily handed over to clients with a strong supply ability from top manufacturers, suppliers, and traders. Expenditure on logistics is minimized by efficient packaging and reliable delivery systems. Globally, its exported to sought-after international markets, acclaimed for its durability and top performance. Whether ordered in bulk or specific quantities, you can rely on prompt and hassle-free shipment every time.

Versatility Across Applications

The 16250 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED finds use in a broad range of industries, from die and mould machining to 3D contouring and intricate milling jobs. This tool is ideal for both manual and machine-inserted operations, performing exceptionally on-site in workshops, production floors, or tool rooms. Its mirror-like surface finish and precise tolerance make it suitable for finishing and semi-finishing of copper, aluminum, brass, and soft steels, ensuring consistent quality in every application.

Distribution & Market Reach: Domestic and Global

Primarily dispatched across Indias main domestic market, this end mill is readily handed over to clients with a strong supply ability from top manufacturers, suppliers, and traders. Expenditure on logistics is minimized by efficient packaging and reliable delivery systems. Globally, its exported to sought-after international markets, acclaimed for its durability and top performance. Whether ordered in bulk or specific quantities, you can rely on prompt and hassle-free shipment every time.

FAQs of 16250 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED:

Q: How is the 16250 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED used in industrial machining?

A: The tool is used for precision milling, 3D contouring, and finishing or semi-finishing applications in industries such as die and mould making, particularly on copper, aluminum, brass, and soft steel workpieces.Q: What benefits does the TiCN coating provide for this ballnose end mill?

A: The TiCN (Titanium Carbonitride) coating offers enhanced wear resistance, reduced friction, and improved hardness (up to 55 HRC), resulting in longer tool life and smoother cutting operations.Q: Where can this tool be applied for optimal results?

A: It is best applied in professional workshop settings, CNC machining centers, and tool rooms where high-speed, high-precision finishing tasks are performed on soft metals and alloys.Q: What is the process of chip evacuation with this end mill?

A: This ballnose end mill is designed for excellent chip removal, ensuring efficient evacuation during high-speed cutting while minimizing clogging and heat buildup.Q: When should I select this particular ballnose for my machining needs?

A: Select this tool when you require precise finishing, semi-finishing, or 3D contouring on copper, brass, aluminum, or soft steels, especially where mirror-like surface finish and tight tolerance are critical.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें