Specification

- टूल टाइप

- Ballnose End Mill

- स्पिंडल स्पीड

- Recommended: 8000-14000 rpm (varies on machine/application)

- कटिंग स्पीड

- Dependent on material and size, typically 120-180 m/min for copper

- एप्लीकेशन

- High precision machining, Finishing of copper and non-ferrous materials

- शोर का स्तर

- Low

- प्रॉडक्ट टाइप

- End Mill - Ballnose (4 Flute)

- मटेरियल

- Copper Alloy (suitable for machining copper and copper alloys)

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- ड्राइव टाइप

- वजन (किग्रा)

- Approx 0.02

- आयाम (एल* डब्ल्यू* एच)

- Varies by size (overall length, shank diameter, flute length)

- क्षमता

- High precision cutting for non-ferrous metals

- फ़ीचर

- रंग

About

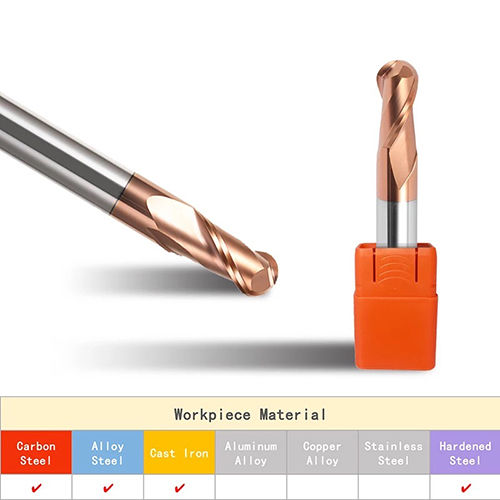

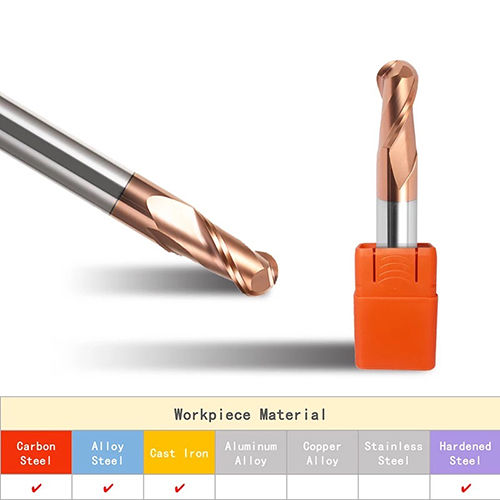

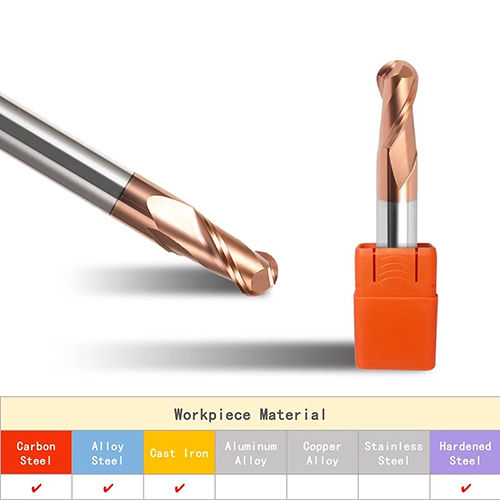

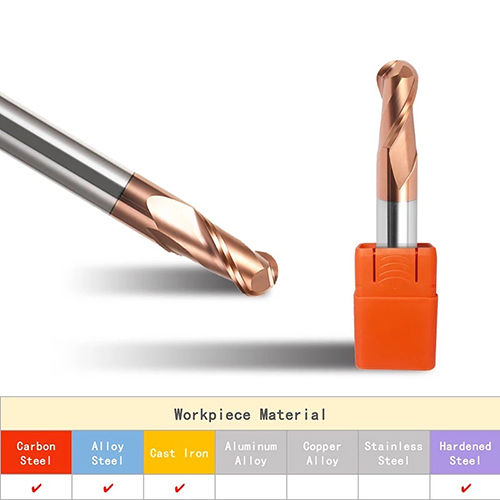

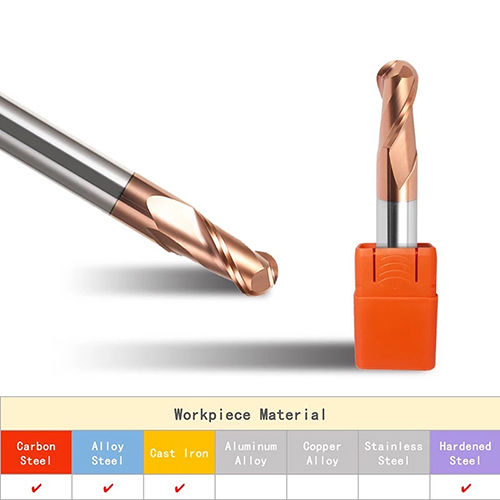

The 4100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED end mill emerges as a popular and elite solution for precision machining of copper and non-ferrous alloys. Noteworthy for its stellar four-flute design, this tool is flawlessly engineered with a 55 HRC hardness and advanced Titanium Carbonitride (TiCN) coating, ensuring ultra-smooth cuts even in demanding dry or wet conditions. Its ballnose geometry and high-shank durability make it the preferred choice among skilled professionals for procuring superior finishing, extended tool lifespan, and high-capacity precision slotting, contouring, and finishing tasks.

Expertly Utilized in Precision Fields

The 4100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED is frequently used by elite machinists and industry professionals engaged in high-precision slotting, contouring, and finishing. Its noteworthy combination of a flawless ballnose edge and durable TiCN coating grants a stellar competitive edge, especially when machining copper and related alloys. Employers in electrical, aerospace, and fine component manufacturing industries procure this end mill for achieving meticulous standards in both dry and wet machining environments.

Reliable Supply, Prompt Delivery, and Global Reach

Order completion for the 4100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED is streamlined to ensure both small and large batch requirements are met efficiently. Secure shipping and careful packaging promise flawless tool integrity upon arrival. With prompt delivery timelines, this product enjoys significant demand across main export markets, including India, Europe, and Southeast Asia. Reliable distribution and trader networks ensure on-time delivery and hassle-free procurement for domestic and international customers.

Expertly Utilized in Precision Fields

The 4100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED is frequently used by elite machinists and industry professionals engaged in high-precision slotting, contouring, and finishing. Its noteworthy combination of a flawless ballnose edge and durable TiCN coating grants a stellar competitive edge, especially when machining copper and related alloys. Employers in electrical, aerospace, and fine component manufacturing industries procure this end mill for achieving meticulous standards in both dry and wet machining environments.

Reliable Supply, Prompt Delivery, and Global Reach

Order completion for the 4100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED is streamlined to ensure both small and large batch requirements are met efficiently. Secure shipping and careful packaging promise flawless tool integrity upon arrival. With prompt delivery timelines, this product enjoys significant demand across main export markets, including India, Europe, and Southeast Asia. Reliable distribution and trader networks ensure on-time delivery and hassle-free procurement for domestic and international customers.

FAQs of 4100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED:

Q: How does the TiCN coating improve tool performance?

A: The Titanium Carbonitride (TiCN) coating enhances the wear resistance, hardness, and lifespan of the end mill, enabling higher cutting speeds and stellar surface finishes especially on copper and non-ferrous materials.Q: What are the specific usage scenarios for the 4100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED end mill?

A: This tool is ideal for precision slotting, contouring, and finishing tasks in both wet and dry machining environments, notably for copper and copper alloy components in electrical, aerospace, and manufacturing industries.Q: Where is the 4100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED commonly supplied and who are the main users?

A: It is primarily supplied to machining workshops, manufacturers, and precision component facilities, with a broad user base in India, Europe, and Southeast Asia.Q: What is the recommended spindle speed for optimal usage?

A: For the best results, a spindle speed between 8000 and 14000 rpm is recommended, though this may vary according to machine setup and application requirements.Q: How can one benefit from procuring this end mill compared to alternatives?

A: With its elite 4-flute design and TiCN coating, users benefit from enhanced tool life, reduced wear, exceptional cutting performance, and high precision finishes, making it a noteworthy investment for demanding machining jobs.Q: What is the process for ordering and delivery of this product?

A: Orders can be placed through authorized distributors or suppliers, who ensure secure shipping and prompt delivery, supported by robust packaging and tracking for order completion and customer satisfaction.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें