Specification

- शोर का स्तर

- Low

- स्पिंडल स्पीड

- 10,000 - 30,000 rpm

- टूल टाइप

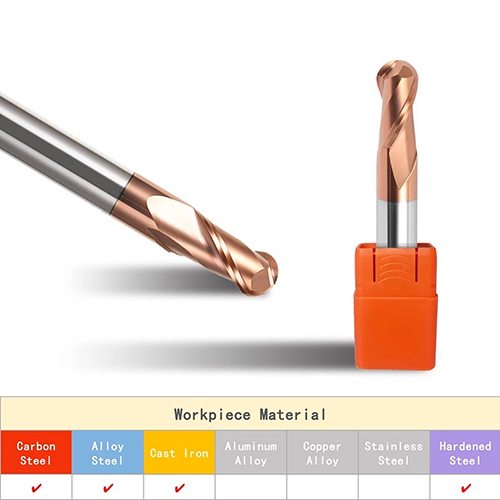

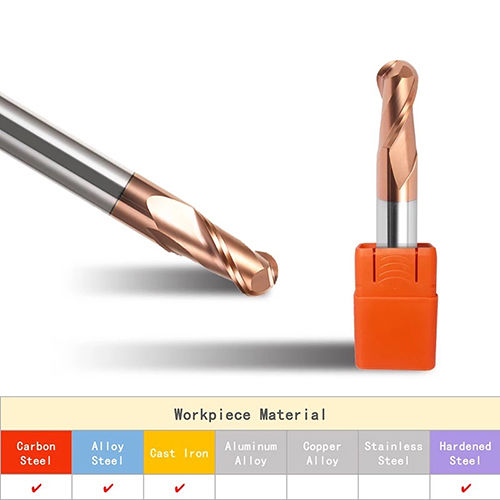

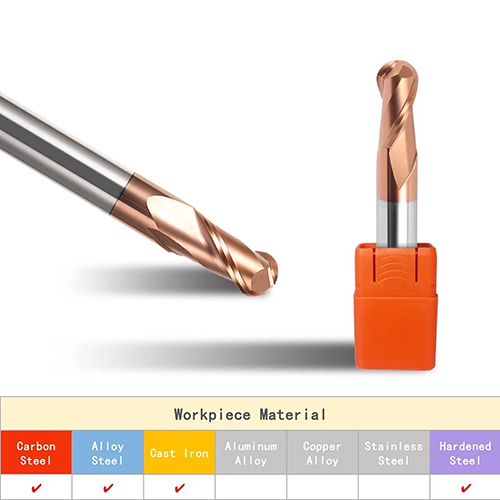

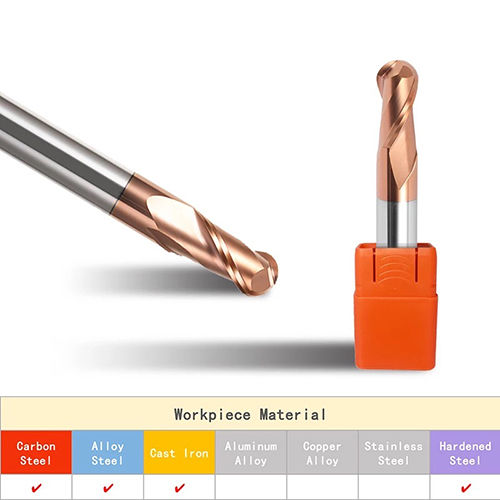

- 4 Flute Ballnose End Mill

- एप्लीकेशन

- Milling, Cutting, Engraving

- कटिंग स्पीड

- 60 - 90 m/min

- प्रॉडक्ट टाइप

- End Mill Cutter

- मटेरियल

- Copper

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- कंट्रोल सिस्टम

- ड्राइव टाइप

- वजन (किग्रा)

- 0.15 kg

- आयाम (एल* डब्ल्यू* एच)

- 75mm x 10mm x 10mm

- क्षमता

- High precision cutting

- फ़ीचर

- रंग

About

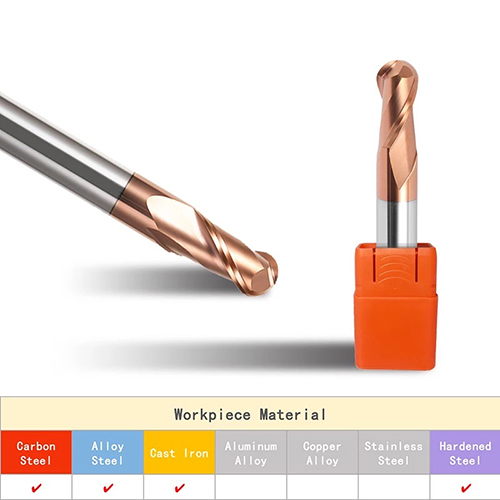

Experience the wondrous performance of the 475 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED end mill! With its prodigious Titanium Carbonitride (TiCN) coating and robust 55 HRC hardness, this tool ensures inestimable durability and supreme surface smoothness. Its 4 flutes, precision ballnose geometry, and high-precision 0.01mm tolerance deliver impeccable results, whether youre milling, engraving, or cutting. Designed for versatility across hardened steel, copper, titanium, and more. Avail this unbeatable priceorder today in India from leading distributors, manufacturers, and suppliers!

Remarkable Material and Versatile Applications

Crafted from high-quality copper with an advanced TiCN coating, the 475 4FLUTE BALLNOSE ensures enhanced hardness and longevity. Its inestimable performance excels across hardened steel, alloy steel, tool steel, copper, graphite, and titanium. Equipped for milling, cutting, and engraving, its ideal for workshops, manufacturing units, and custom fabrication projects requiring sublime precision. This tools area of application encompasses both dry and wet cutting environments, making it a reliable asset for machinists and toolmakers alike.

Global Outreach and Logistical Excellence

We proudly offer the 475 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED to a vast export market, servicing industrial hubs worldwide with reliable drop-off and timely delivery. Expect your order to be fulfilled promptly, keeping your outlay minimal and your operations running efficiently. Certified to meet stringent industry standards, each shipment promises excellence and dependability. Leverage our global network and robust supply chain for quick, secure delivery, ensuring uninterrupted productivity on every machining project.

Remarkable Material and Versatile Applications

Crafted from high-quality copper with an advanced TiCN coating, the 475 4FLUTE BALLNOSE ensures enhanced hardness and longevity. Its inestimable performance excels across hardened steel, alloy steel, tool steel, copper, graphite, and titanium. Equipped for milling, cutting, and engraving, its ideal for workshops, manufacturing units, and custom fabrication projects requiring sublime precision. This tools area of application encompasses both dry and wet cutting environments, making it a reliable asset for machinists and toolmakers alike.

Global Outreach and Logistical Excellence

We proudly offer the 475 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED to a vast export market, servicing industrial hubs worldwide with reliable drop-off and timely delivery. Expect your order to be fulfilled promptly, keeping your outlay minimal and your operations running efficiently. Certified to meet stringent industry standards, each shipment promises excellence and dependability. Leverage our global network and robust supply chain for quick, secure delivery, ensuring uninterrupted productivity on every machining project.

FAQs of 475 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED:

Q: How does the TiCN coating benefit the 475 4FLUTE BALLNOSE COPPER end mill?

A: The Titanium Carbonitride (TiCN) coating significantly enhances the tools hardness, wear resistance, and cutting performance, ensuring longer service life and superior surface finishes on various materials.Q: What materials can be processed with this end mill?

A: This end mill is suitable for milling, cutting, and engraving hard and soft materials such as hardened steel, alloy steel, tool steel, copper, graphite, and titanium.Q: Where can I use the 475 4FLUTE BALLNOSE in my workshop?

A: It is ideal for precision machining tasks in industrial manufacturing, toolrooms, and prototyping labs that demand reliable results on metals and non-metals alike.Q: What is the typical delivery time after placing an order?

A: Delivery times are prompt, with most orders fulfilled and dropped off within a standard industrial delivery schedule, subject to your location and shipping method.Q: How do I maintain the longevity of this tool?

A: Store the tool in a cool, dry place, avoid humidity, and ensure proper cleaning after use. Adhering to correct spindle speeds and cutting conditions will also maximize its lifespan.Q: When should I use dry vs. wet cutting with this end mill?

A: This tool is compatible with both dry and wet cutting. Use wet cutting for enhanced cooling when working on harder materials, or opt for dry cutting for quicker jobs and simpler setups.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें