Specification

- पावर सोर्स

- Electric

- स्पिंडल स्पीड

- Up to 40,000 rpm

- टूल टाइप

- 2 Flute Ball Nose End Mill

- कटिंग स्पीड

- Varies by Material, Up to 250 m/min

- एप्लीकेशन

- Milling, Contouring, Shaping Metals and Non-Ferrous Materials

- शोर का स्तर

- Low

- प्रॉडक्ट टाइप

- End Mill Cutter

- मटेरियल

- Copper

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- कंट्रोल सिस्टम

- ड्राइव टाइप

- वोल्टेज

- 220V

- वजन (किग्रा)

- 0.05

- आयाम (एल* डब्ल्यू* एच)

- Varies (Diameter x Flute Length x Overall Length)

- क्षमता

- High Precision Milling

- फ़ीचर

- रंग

About

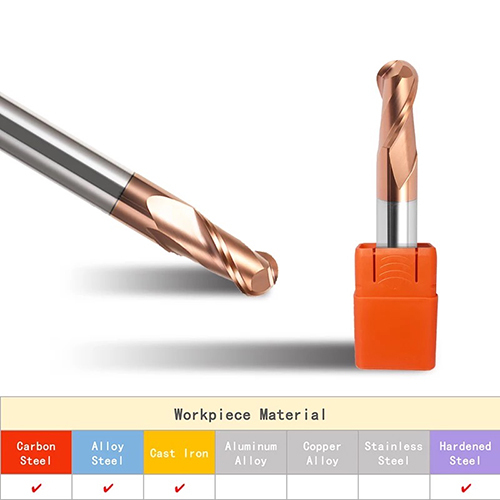

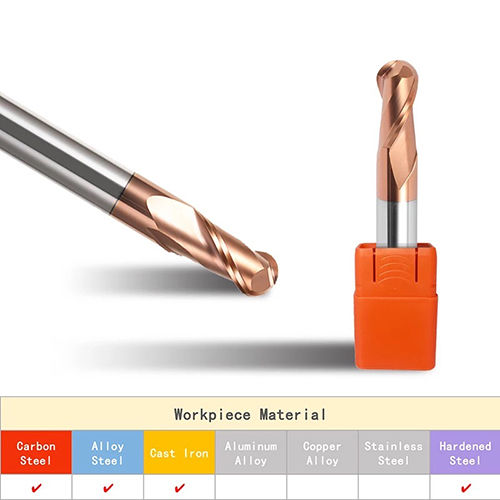

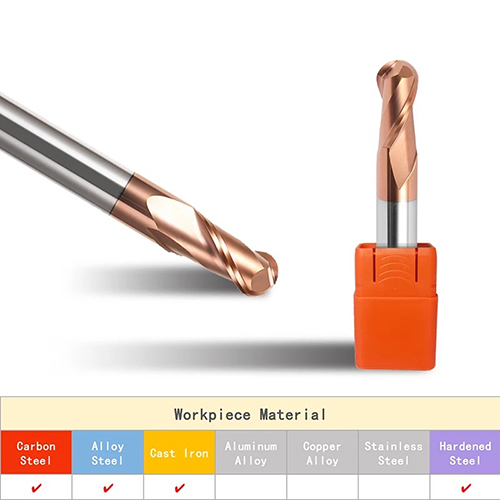

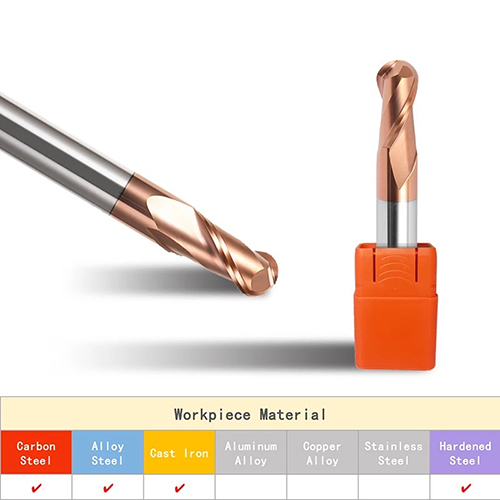

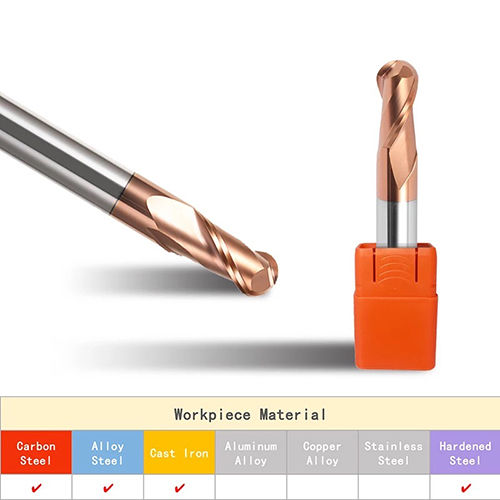

Spotlight on precision: the 550 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED, now available in a scarce sale for those who demand preeminent performance. With exceptional 55 HRC hardness, sublime TiCN coating, and a high-precision tolerance within 0.01 mm, this cylindrical end mill is tailored for intricate CNC milling. It effortlessly shapes copper, brass, aluminum, and non-ferrous alloys, while its superior resistance to wear, heat, and built-up edge formation ensures enduring production quality. Ideal for mold and die production, electrical components, and automated machining lines.

Versatile Precision Tool for Industrial Applications

The 550 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED end mill is remarkably utilized for cutting, shaping, and contouring a spectrum of metals and non-ferrous materials. Engineered from robust copper and armed with sublime TiCN coating, it excels in heat and wear resistance. Its application extends to plant operations for CNC milling, mold and die manufacturing, and electrical component machining, guaranteeing high productivity and exceptional surface finishes.

Domestic Market Reach with Reliable Dispatch

With a strong valuation in the main domestic market, the 550 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED is promptly dispatched from stock. Backed by substantial supply ability, samples can be arranged for client evaluation. Each unit undergoes rigorous packing & dispatch protocols, ensuring secure delivery and optimal condition upon arrival. Distributed and supported across India by trusted manufacturers, suppliers, and traders, it promises reliability and availability for industrial users.

Versatile Precision Tool for Industrial Applications

The 550 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED end mill is remarkably utilized for cutting, shaping, and contouring a spectrum of metals and non-ferrous materials. Engineered from robust copper and armed with sublime TiCN coating, it excels in heat and wear resistance. Its application extends to plant operations for CNC milling, mold and die manufacturing, and electrical component machining, guaranteeing high productivity and exceptional surface finishes.

Domestic Market Reach with Reliable Dispatch

With a strong valuation in the main domestic market, the 550 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED is promptly dispatched from stock. Backed by substantial supply ability, samples can be arranged for client evaluation. Each unit undergoes rigorous packing & dispatch protocols, ensuring secure delivery and optimal condition upon arrival. Distributed and supported across India by trusted manufacturers, suppliers, and traders, it promises reliability and availability for industrial users.

FAQs of 550 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED:

Q: How does the TiCN coating benefit the 550 2FLUTE BALLNOSE end mill?

A: The Titanium Carbonitride (TiCN) coating significantly enhances wear and heat resistance, reducing tool degradation and extending cutting life, especially in demanding CNC milling tasks.Q: What materials are suitable for machining with this tool?

A: It is engineered to perform excellently on copper, brass, aluminum, and various non-ferrous alloys, delivering super fine surface finishes on these materials.Q: Where can I use the 550 2FLUTE BALLNOSE COPPER 55HRC TiCN COATED?

A: This end mill is tailored for plant applications such as CNC milling, mold and die industries, and electrical component manufacturing, thanks to its high precision and robust material features.Q: What is the process for ordering samples?

A: Samples can be requested through authorized distributors or suppliers. Once your request is valued and confirmed, samples are packed and dispatched securely for evaluation.Q: When is it advantageous to use this tool in my machining process?

A: It is advantageous during high precision milling operations, particularly when working with non-ferrous metals at high spindle speeds, requiring minimal tool wear and exceptional chip evacuation.Q: How is packing and dispatch managed for bulk orders?

A: All bulk orders undergo systematic packing & dispatch, with each unit securely packaged to ensure it reaches you in optimal condition, supporting your workflow without disruption.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें