Price 63 आईएनआर/ टुकड़ा

MOQ : 1 टुकड़ा

Specification

- टूल टाइप

- Indexable milling and turning insert

- एप्लीकेशन

- For CNC machining, milling, turning, and threading

- कटिंग स्पीड

- Up to 350 m/min (material dependent)

- शोर का स्तर

- Depends on operating conditions

- स्पिंडल स्पीड

- Depends on machinery, typically up to 8000 RPM

- प्रॉडक्ट टाइप

- Turning Insert

- मटेरियल

- Carbide

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- वजन (किग्रा)

- 0.02 kg (approx. per insert)

- आयाम (एल* डब्ल्यू* एच)

- Varies (approx. 9.7 x 3.4 x 3.67 mm)

- क्षमता

- Multi-turn applications

- फ़ीचर

- रंग

- Chip Breaker

- Integrated with optimized geometry

- Tolerance

- ISO Standard

- Coating

- TiN or CVD/PVD coated for improved life

- Grade

- Suitable for steel, stainless steel, and cast iron machining

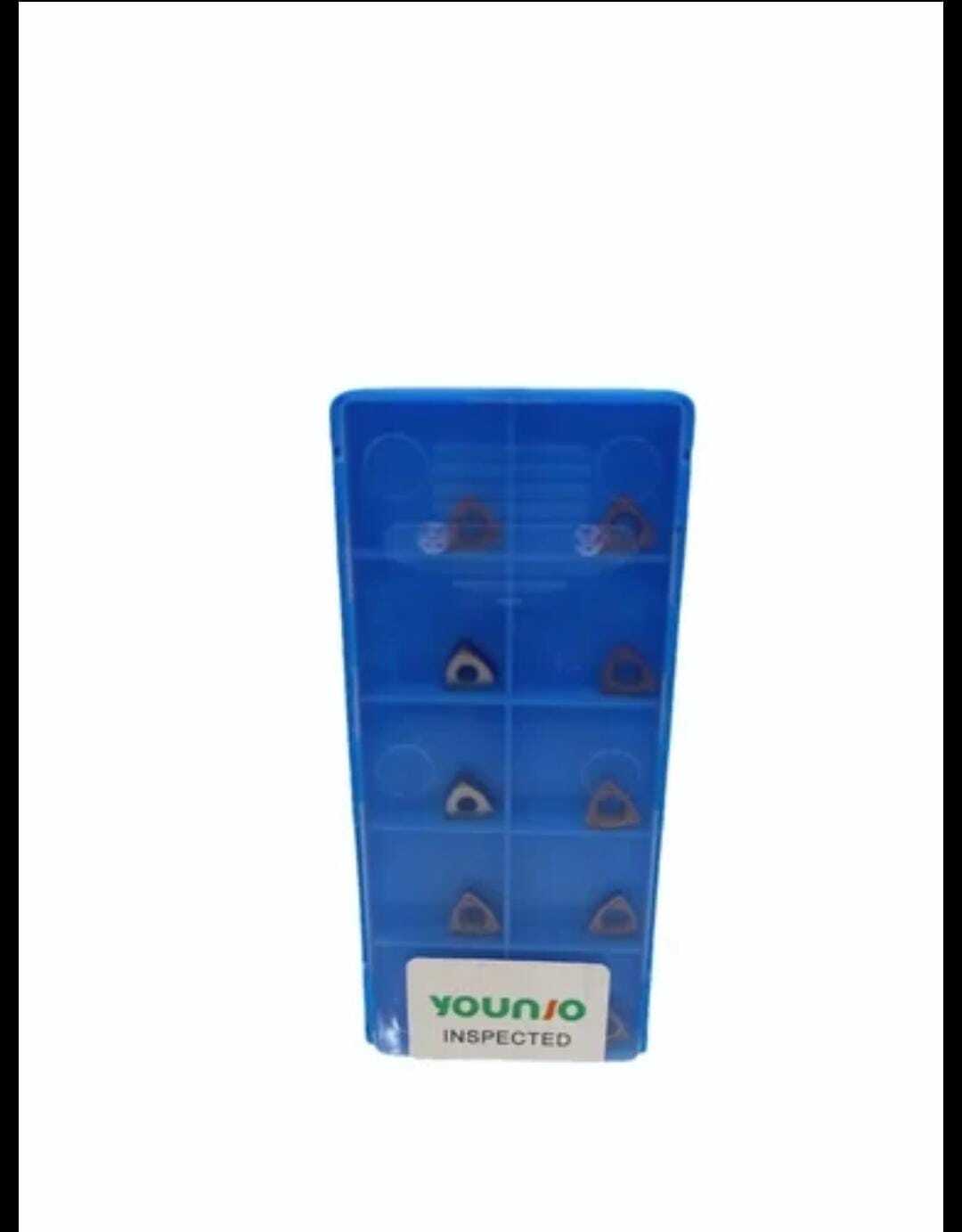

- Insert Shape

- Trigon (triangular convex)

- Pack Quantity

- 10 inserts per box

- Insert Size

- 03 (nominal size)

- Clamping Method

- Screw or clamp fit

- Rake Angle

- Positive rake

- Edge Preparation

- Sharp with honed edge

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- भुगतान की शर्तें

- मुख्य घरेलू बाज़ार

About

It is intended to be used for both turning and boring applications, especially ideal for roughing. When a cutting edge of the WNMM insert, a turning insert, becomes dull, you just need to rotate the insert in the holder to use the sharp edge.Precision Performance for Versatile Machining

WCMT 03 inserts are designed to handle multiple-turn applications with high accuracy. Their trigon shape, sharp honed edge, and optimized chip breaker geometry allow for reliable, clean cuts in steel, stainless steel, and cast iron. The positive rake angle enhances chip flow and reduces cutting resistance, enabling precision CNC machining.

Durable Coatings for Longer Tool Life

These inserts come coated with either Titanium Nitride (TiN) or advanced CVD/PVD layers, providing superior resistance to wear and heat. Whether used in high-speed turning or milling, the coatings ensure consistent performance, minimize downtime for insert changes, and maintain stable operations even at spindle speeds up to 8000 RPM.

Easy Handling and Superior Clamping

Featuring screw or clamp fit methods, WCMT 03 inserts can be swiftly and securely installed in compatible tool holders. The standardized dimensions simplify insert replacement and setup. High manufacturing standards ensure each insert fits accurately, contributing to operational efficiency and reducing tool change time.

FAQ's of WCMT 03 INSERTS:

Q: How do I correctly install WCMT 03 inserts in my CNC tool holder?

A: You can install WCMT 03 inserts using either the screw or clamp fit, depending on your tool holder design. Ensure the insert seats firmly against the pocket with the cutting edge aligned correctly. Secure the insert using the recommended torque to prevent movement during operation.Q: What are the primary benefits of using WCMT 03 inserts for steel, stainless steel, and cast iron?

A: The inserts' carbide material, integrated chip breaker, and advanced TiN or CVD/PVD coatings combine to offer high wear resistance, extended tool life, and cleaner cuts. This makes them highly effective for precision CNC machining on steel, stainless steel, and cast iron components.Q: When should I replace WCMT 03 inserts during a production run?

A: Replace the inserts when you observe signs of wear such as reduced cutting performance, poor surface finish, or visible chipping on the edge. The advanced coatings and robust edge preparation, however, extend service life and reduce changeover frequency.Q: Where can WCMT 03 inserts be sourced in India?

A: WCMT 03 inserts are available from authorized distributors, manufacturers, suppliers, and traders across India. Purchase from reputable sources to ensure you receive genuine, ISO-standard inserts for your operations.Q: What is the process for selecting the right grade and coating for my machining application?

A: Choose the grade based on the workpiece material: the offered grades are suitable for steel, stainless steel, and cast iron. Opt for TiN or CVD/PVD coatings depending on your required wear resistance and type of machining (e.g., roughing versus finishing). Consult your tooling supplier for specific recommendations.Q: How can I maximize the benefit of using WCMT 03 inserts in multi-turn applications?

A: To maximize performance, ensure correct installation, select appropriate spindle speeds and feeds (up to 8000 RPM and 350 m/min cutting speed, material dependent), and regularly monitor insert condition. Keep the work environment clean and minimize vibration for optimum results.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें