Specification

- कटिंग स्पीड

- Recommended: 150-450 m/min

- टूल टाइप

- 4 Flute Ballnose End Mill

- पावर सोर्स

- Machining Tool Driven

- स्पिंडल स्पीड

- Up to 20,000 RPM (depending on tool size and machine)

- एप्लीकेशन

- High-precision milling, Copper, Aluminium and softer metal cutting

- शोर का स्तर

- Depends on machining parameters

- प्रॉडक्ट टाइप

- End Mill Cutter

- मटेरियल

- Solid Carbide Copper

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- वजन (किग्रा)

- 0.015 kg

- आयाम (एल* डब्ल्यू* एच)

- Varies as per size (e.g. 100mm x 10mm x 10mm)

- क्षमता

- Precision Milling

- फ़ीचर

- रंग

About

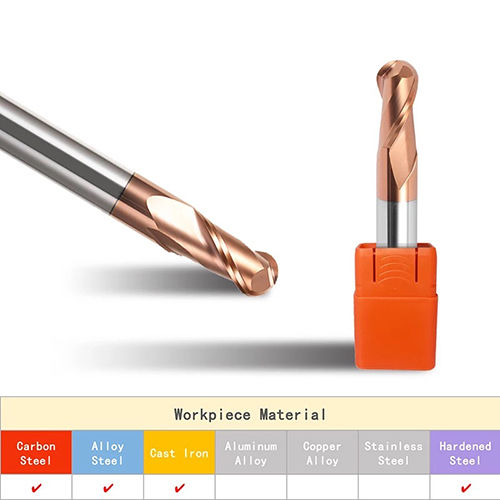

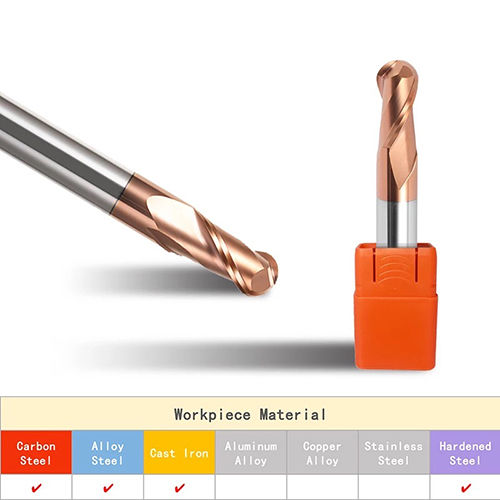

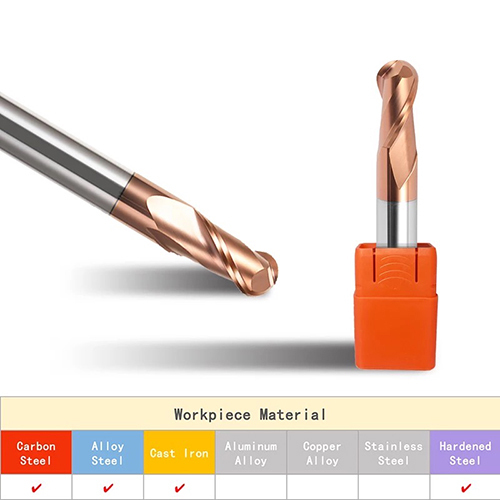

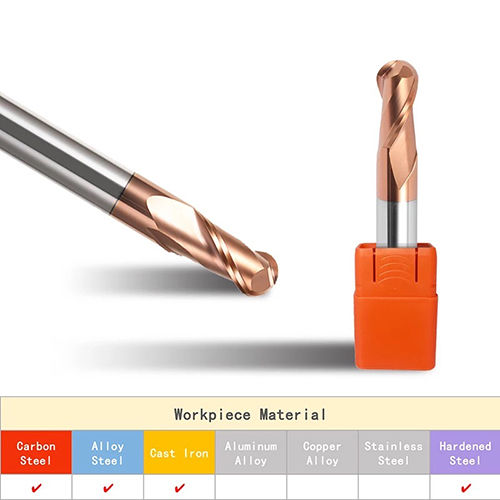

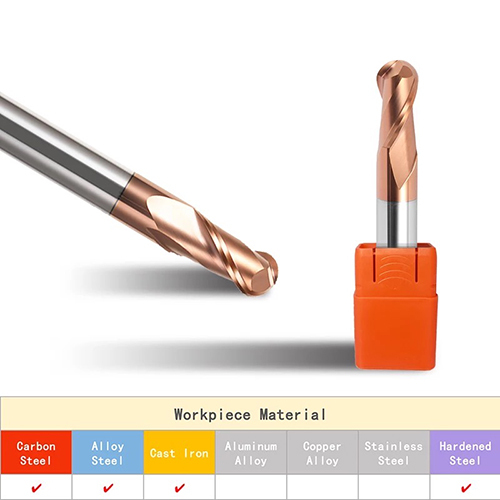

Capitalise on the formidable performance of the 3100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED end mill, engineered for matchless precision and gilt-edged efficiency. Featuring a top-tier solid carbide copper body and advanced TiCN coating, this tool boasts a special rate of wear resistance and a hardness of 55 HRC. With four flutes, a 35 helix angle, and 0.01 mm tolerance, it guarantees exceptional surface finish and extended tool life. Suited for both dry and wet cutting environments, its perfect for stainless steel, alloy steel, cast iron, copper, and aluminum, making it the ideal choice for traders, distributors, and manufacturers across India.

Versatile Application and End Users

The 3100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED end mill is widely used in high-precision milling applications. It is trusted by professional machinists, manufacturers, and suppliers for cutting copper, aluminum, stainless steel, and alloy steel in both automated and manual setups. Usage includes media such as dry and wet environments, making these tools an indispensable asset for traders and distributors requiring consistent and accurate performance.

Exports, Delivery, and Certifications

This matchless cutting tool enjoys a formidable export rate to major markets, with reliable delivery times and superior packaging ensuring product valuation stays high. The 3100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED is certified for accuracy and performance, making it a top choice for global manufacturers and suppliers looking for dependable milling solutions. Our rapid dispatch and secure handling reinforce customer confidence and satisfaction in every transaction.

Versatile Application and End Users

The 3100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED end mill is widely used in high-precision milling applications. It is trusted by professional machinists, manufacturers, and suppliers for cutting copper, aluminum, stainless steel, and alloy steel in both automated and manual setups. Usage includes media such as dry and wet environments, making these tools an indispensable asset for traders and distributors requiring consistent and accurate performance.

Exports, Delivery, and Certifications

This matchless cutting tool enjoys a formidable export rate to major markets, with reliable delivery times and superior packaging ensuring product valuation stays high. The 3100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED is certified for accuracy and performance, making it a top choice for global manufacturers and suppliers looking for dependable milling solutions. Our rapid dispatch and secure handling reinforce customer confidence and satisfaction in every transaction.

FAQs of 3100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED:

Q: How does the TiCN coating benefit the 3100 4FLUTE BALLNOSE COPPER 55HRC end mill?

A: TiCN (Titanium Carbonitride) coating improves wear resistance, increases hardness, extends tool life, and ensures a smoother finish during high-precision milling.Q: What materials are suitable for machining with this ballnose end mill?

A: It is ideal for cutting copper, aluminum, stainless steel, alloy steel, and cast iron, offering versatile application across a range of softer and harder metals.Q: When should I use dry versus wet cutting environments with this tool?

A: This end mill performs well in both dry and wet cutting setups. Wet cutting is recommended for heat-sensitive metals, while dry cutting suits rapid milling operations and certain alloys.Q: Where is the 3100 4FLUTE BALLNOSE COPPER 55HRC TiCN COATED mainly exported?

A: It is primarily exported to major industrial markets globally, including distributors and manufacturers across Asia, Europe, and North America.Q: What is the process for achieving high precision with this end mill?

A: High precision is ensured through consistent feed rates, optimal spindle speeds up to 20,000 RPM, and precise tool alignment based on your machinerys specifications.Q: What is the recommended feed rate for optimal performance?

A: A feed rate of 0.05-0.15 mm/tooth is recommended to maintain both tool life and superior surface finish during milling.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें